The know-how for constant quality

We ensure that you will always receive the same quality.

It is even fixed in our contracts: We deliver constant quality throughout the year – no matter what.

This reliability is made possible through our specific know-how, which allows us to tailor the product specifications according to our customers’ needs. Our long established experience makes us experts at consistency.

It clearly shows in the great taste of our products and even more so in our satisfied customers!

Our internal laboratory is responsible for quality assurance and food safety and oversees all production processes. Our agronomists also keep a close eye on our fruit during the growing period.

The know-how for constant quality

We ensure that you will always receive the same quality.

It is even fixed in our contracts: We deliver constant quality throughout the year – no matter what.

This reliability is made possible through our specific know-how, which allows us to tailor the product specifications according to our customers’ needs. Our long established experience makes us experts at consistency.

It clearly shows in the great taste of our products and even more so in our satisfied customers!

Our internal laboratory is responsible for quality assurance and food safety and oversees all production processes. Our agronomists also keep a close eye on our fruit during the growing period.

The quality of our purees, juices and concentrates is strictly monitored.

Our expertise and highly qualified employees ensure the best quality.

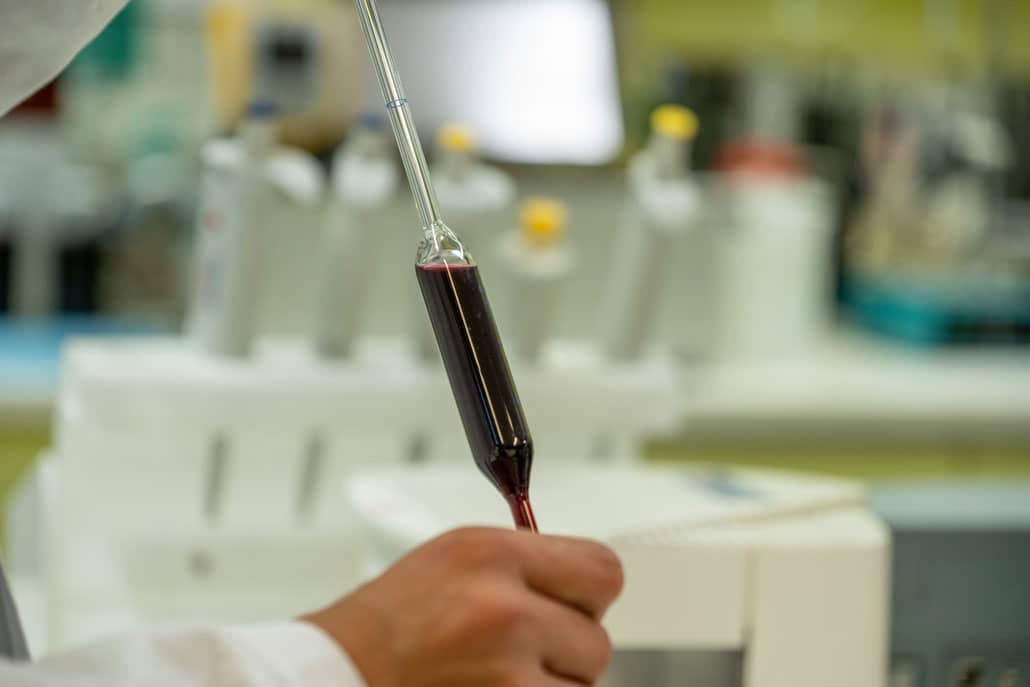

The latest laboratory equipment combined with classical analyses result in optimal quality control.

Our internal laboratory guarantees highest product safety.

Organoleptic testing is conducted using all senses before loading.

The quality of our purees, juices and concentrates is strictly monitored.

Our expertise and highly qualified employees ensure the best quality.

The latest laboratory equipment combined with classical analyses result in optimal quality control.

Our internal laboratory guarantees highest product safety.

Organoleptic testing is conducted using all senses before loading.

A wide range of products and the enormous storage capacity are two of our greatest strengths.

For each product we have a detailed Zipperle product specification or else we can follow a customer specification. Either way, our internal laboratory strictly checks if the required parameters are complied with. Click here for our product overview.

Our internal laboratory is not just monitoring compliance with product specifications.

It is also the control centre of the company’s entire production facilities and therefore keeps a close eye on the entire manufacturing process. Training as fruit juice technicians in Geisenheim and working hands on along our production lines are basic prerequisites for our skilled laboratory staff.

Therefore, all of our laboratory staff have worked in several departments of our processing facilities and have the profound knowledge necessary to guide the production staff appropriately.

The latest laboratory equipment combined with classical analyses result in optimal quality control.

We use automatic instruments for titration and enzymatic analyses and monitor patulin and ergosterol levels, as well as other residues closely with HPLC. We leave further analyses, which are essential especially in the organic and baby food sector, to our expert partner laboratories.

We also maintain a lively exchange with experts from the Gesellschaft für Lebensmittel-Forschung (GfL) and conduct a large number of analyses with them each year regarding the marketability and authenticity of our conventional products.

Last but not least, our in-house laboratory for microbiology plays an important role in monitoring and ensuring our product and operational hygiene.

It is as essential to our product safety as is the continuation and maintenance of our Food-Safety-Management-System, into which our production and control processes are embedded.

The annual certification according to FSSC 22000 is proof of our rigorous quality assurance measures.

Another guarantee of our authentic and impeccable products is our voluntary participation in the control system of the fruit juice industry by the SGF IRMA.

One of the most important aspects of our quality control remain organoleptic tests, which are conducted using all senses before loading.

It is the only way to ensure that customers and consumers can safely enjoy our delicious products. Internal and external organoleptic training of our experts is indispensable. To make sure it is done correctly, we mostly partner with the DLG.

Organoleptic properties and the compliance with our customers’ specifications are meticulously examined before any product is cleared for loading or filling.

Development of an eco-sustainable bioprocessing for making low sugar fruit juices

R&D Project SMARTJUICE

The main source of excess sugar in the human diet is constituted by sugary drinks. Excessive sugar consumption is considered one of the determining causes of obesity and, consequently, is associated with a higher prevalence of risk factors for metabolic and cardio-metabolic diseases. Although natural juices are perceived to be healthier, they favour the energy and calorie intake of more portions of fresh fruit. Consequently, natural juices have a sugar content similar to that of sugary drinks, and once metabolised they induce the same biological response. In addition, the political orientation to introduce the sugar tax in many countries might limit the production of drinks with a high sugar content, and consequently reduce the daily intake of sugars.

The project Smartjuice aims to develop a new fruit drink with reduced sugar content produced in a natural way, in which the nutritional and sensory quality of the fruit is preserved.

The challenge of the project is monitoring and controlling the catabolism of sugars and the synthesis of natural sweeteners within fruit juices and natural smoothies without altering their organoleptic characteristics. The use of functional microorganisms and “food grade” enzymes combined with guided fermentation will constitute the natural and sustainable way to achieve this goal. Fermentation is considered one of the most traditional, eco-sustainable and effective examples of biotechnology to ensure the hygienic, sensory and shelf-life properties, and the improvement of the nutritional value of many foods and beverages.

Hans Zipperle AG/S.p.A.

Via Max Valier, 3

39012 Merano (BZ)

South Tyrol – Italy

www.zipperle.it

Tel. +39 0473 274 100

Fax. +39 0473 274 222

Information: zisaft@zipperle.it

Sale: sales@zipperle.it

Purchase: frutta@zipperle.it